How to choose the right transformer for your application isn’t just about voltage and kVA on a datasheet. Selecting the correct unit requires a clear understanding of your load, supply conditions, operating environment, and safety requirements. Getting the specification wrong can lead to overheating, poor efficiency, voltage instability, or reduced equipment life.

At Majestic Transformer Co, we design and manufacture both standard and bespoke transformers for every type of application. The process is always the same, defining the electrical conditions, assessing the load, and selecting a design that will operate reliably for many years. This guide outlines the key considerations our engineers work through when specifying a transformer.

Identify the Load Requirements

The first step is to determine the load the transformer must supply. This includes both the total demand and the nature of the equipment connected.

kVA Rating

Transformers are rated in kVA. To size correctly:

- Determine the full-load current of the equipment.

- Include any starting or inrush currents.

- Add a safety margin for future expansion.

For most installations, a 20% allowance provides enough headroom for operational variations.

Type of Load

Loads fall into three common categories:

- Resistive (heaters, lighting)

- Inductive (motors, compressors)

- Electronic (rectifiers, drives, instrumentation)

Inductive loads produce higher inrush currents. Electronic loads may introduce harmonics or require isolation to prevent interference.

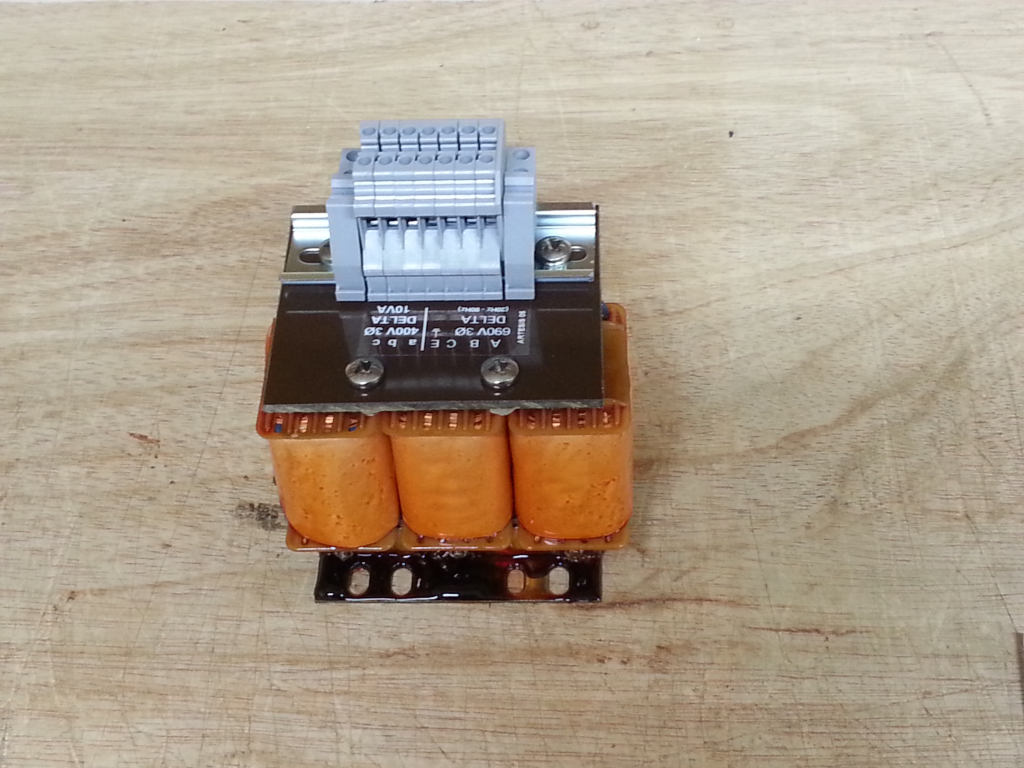

Single-Phase or Three-Phase

If your load is below approximately 10 kVA and only single-phase equipment, a single-phase transformer is typically suitable.

For larger installations, motors, or continuous industrial applications, a three-phase transformer provides better stability and efficiency.

You can also review our comparison guide here: Single-Phase vs Three-Phase Transformers

Determine the Input and Output Voltage

The transformer must match the supply voltage and provide the correct output voltage for the equipment.

Standard UK Supply

Most UK installations operate at:

- 230 V single-phase, 50 Hz

- 400/230 V three-phase, 50 Hz

If your equipment has a non-standard requirement, a step-up or step-down transformer is used to match voltages correctly.

Voltage Accuracy

Some equipment, particularly instrumentation and control systems, requires a tightly regulated voltage.

In these cases:

- Consider transformers with lower impedance.

- Use isolation transformers to stabilise the output.

- Ensure the design supports the required voltage tolerance.

Select the Appropriate Transformer Type

Several transformer types are used across different applications. The choice depends on the electrical characteristics required.

Isolation Transformers

Used where galvanic isolation is needed between primary and secondary circuits.

Typical applications:

- Medical equipment

- Laboratory instruments

- Sensitive electronics

- Noise reduction in industrial environments

Learn more: Isolation Transformers

Auto Transformers

Compact and efficient where isolation is not required.

Common uses:

- Voltage adjustment

- Motor soft starting

- Variations between 230 V and 110 V supplies

See: Auto Transformers

Step-Up / Step-Down Transformers

Used to match equipment designed for different regional voltages with the local supply.

Control and Lighting Transformers

Provide low-voltage power for control panels, PLCs, signalling, and lighting systems.

Bespoke Units

For unique requirements, a fully custom-built transformer may be the best option.

Learn more: Custom Transformers

Assess the Operating Environment

Environmental conditions directly affect transformer performance and longevity.

Ambient Temperature

High temperatures reduce efficiency and shorten insulation life.

Transformers may require:

- Higher temperature class winding materials

- Improved ventilation

- Derating for elevated environments

Ventilation and Cooling

Most transformers are air-cooled (dry-type).

Ensure the installation location:

- Allows sufficient air movement

- Is free from dust, moisture, or corrosive vapours

- Provides access for maintenance

For demanding industrial environments, bespoke enclosures may be required.

Mounting and Enclosure

Common configurations include:

- Wall-mounted units

- Floor-standing transformers

- IP-rated enclosures for harsh environments

- Vibration-resistant mounts for marine or transport applications

For specialist configurations, refer to our Design & Manufacture service

Consider Efficiency and Losses

Transformer losses occur as heat, these are split into:

- Iron losses (constant)

- Copper losses (load-dependent)

When choosing a transformer:

- Ensure the rating matches the expected duty cycle

- Avoid oversizing, which increases iron losses unnecessarily

- Avoid under sizing, which increases copper losses and heat build-up

For continuous operation, a correctly sized three-phase transformer reduces total losses significantly.

Verify Compliance and Safety Standards

For UK and EU installations, transformers must comply with relevant EN standards.

Majestic Transformer Co builds all units in line with:

- BS EN 61558 (Safety of power transformers)

- BS EN 60076 (Power transformers)

- ISO 9001:2015 quality management

Compliance ensures:

- Safe operating temperatures

- Correct insulation levels

- Reliable fault protection

- Long service life

Refer to our: Design & Manufacture Services

When a Bespoke Transformer Is the Better Choice

A standard catalogue transformer may not meet the exact specification. Custom transformers are recommended when you require:

- Unusual voltage combinations

- High inrush loads

- Restricted mounting space

- Environmental protection

- Special winding configurations

- Custom terminations or connectors

Majestic Transformer Co designs and manufactures bespoke units for all sectors, including industrial, marine, medical, and research environments.

Learn more: Custom Transformers

Common Selection Mistakes to Avoid

A transformer may appear suitable on paper but fail under real conditions. Common issues include:

- Under sizing the kVA rating due to motor starting currents

- Ignoring voltage drop on long cable runs

- Selecting an auto transformer when isolation is required

- Failing to consider harmonics from non-linear loads

- Installing in confined spaces with inadequate ventilation

- Using standard enclosures in environments that require IP protection

Avoiding these mistakes ensures reliable, long-term operation.

Transformer Selection Checklist

Before purchasing or specifying a transformer, confirm the following:

- Required input and output voltage

- Load type and kVA rating

- Single-phase or three-phase supply

- Duty cycle and starting current

- Cooling and ventilation requirements

- Environmental conditions and enclosure needs

- Compliance standards

- Need for isolation or voltage conversion

- Space or mounting restrictions

This checklist covers the essential considerations for a safe and reliable installation.

Talk to Our Engineers

If you are unsure which transformer matches your installation, our design team can assist with selection, sizing, and specification. We can develop a transformer tailored to your exact requirements and operating conditions.

Request a Quote or contact our engineering team to discuss your application.