Single-Phase vs Three-Phase Transformers

Whether you’re specifying power for an industrial process, a data centre, or a precision control system, choosing between a single-phase and a three-phase transformer is more than a box-ticking exercise. It affects everything from efficiency and voltage stability to installation costs and future scalability.

At Majestic Transformer Co, we’ve been designing and manufacturing custom-built transformers since 1942, so here’s how we look at the decision from an engineering standpoint.

Understanding The Electrical Fundamentals

Single-Phase Power

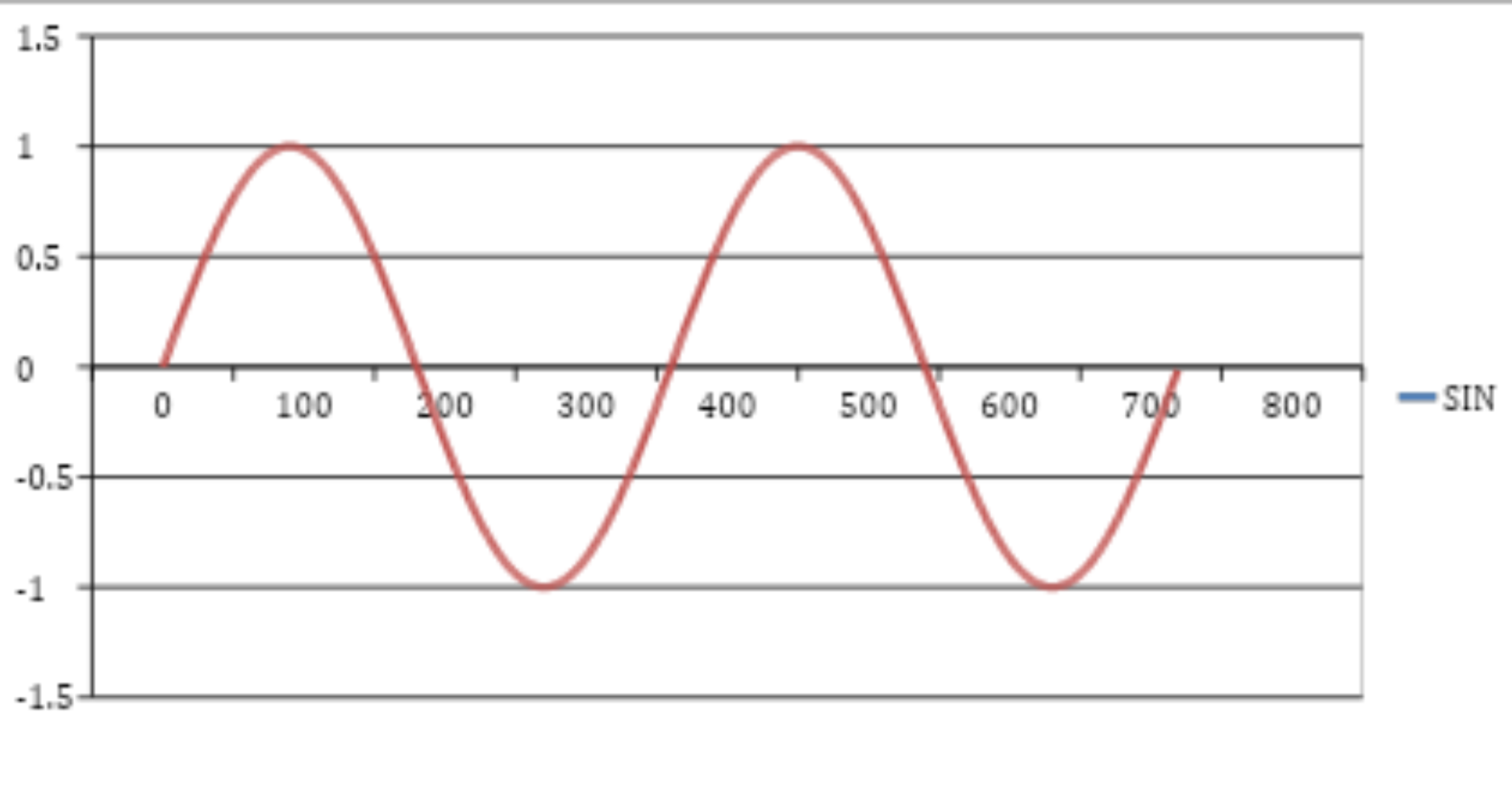

A single-phase transformer operates with one alternating voltage cycle (a single sine wave). It delivers power through two wires, a live and a neutral with the current reversing direction every half-cycle.

It’s simple, reliable, and ideal for lower-power applications, but it suffers from one key limitation: the power flow isn’t constant. The voltage peaks twice per cycle, which creates pulsations in torque and heat generation when powering motors or heavy loads.

Three-Phase Power

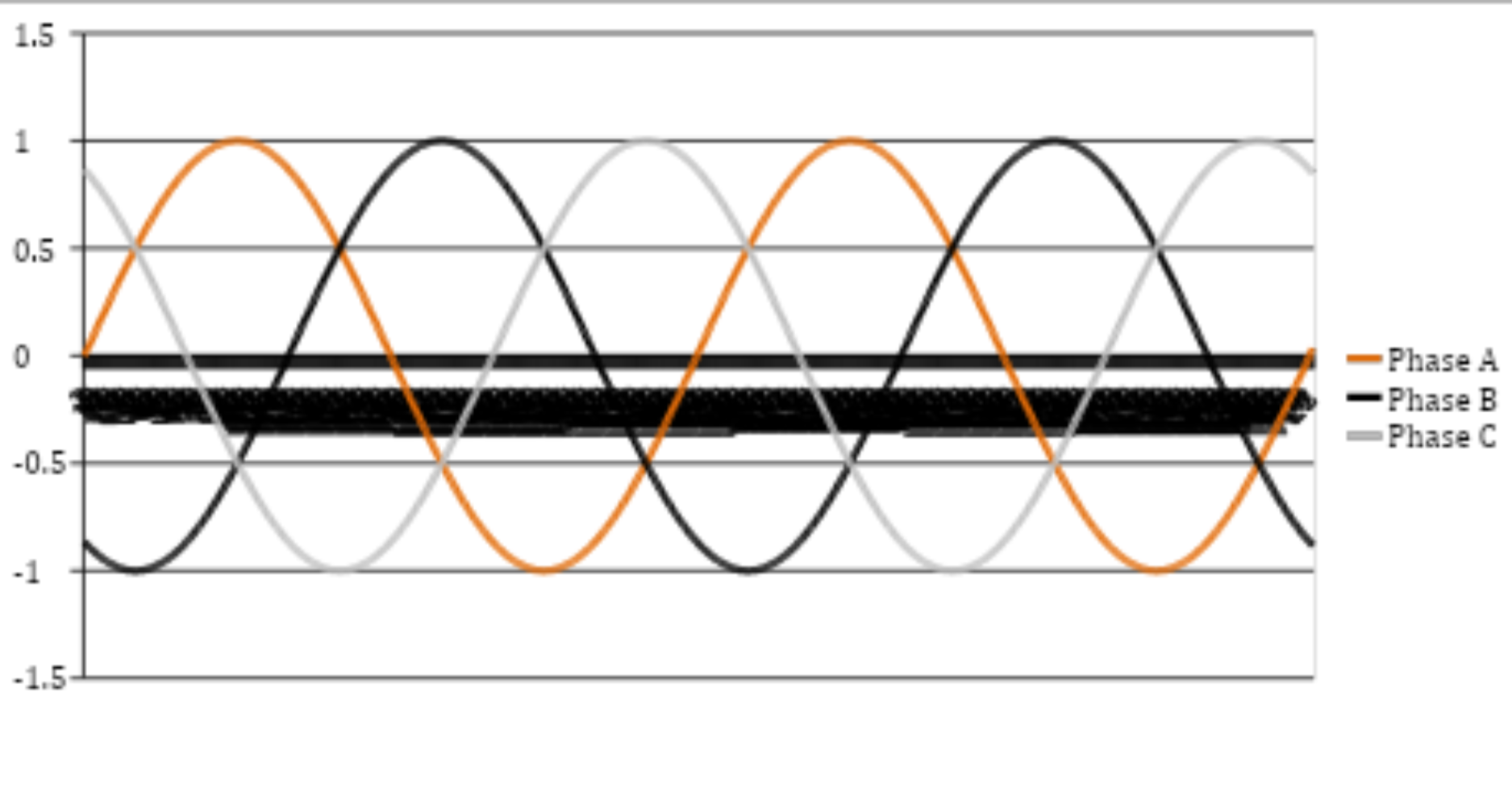

A three-phase transformer uses three alternating currents, each phase offset by 120°. This produces a near-constant power transfer across all three phases, significantly improving efficiency and reducing electrical noise.

The result? Smoother motor operation, lower vibration, reduced copper losses, and less strain on components.

Efficiency and Load Balancing

In single-phase systems, the load is carried entirely on one phase. This is fine for equipment below 10 kVA, think office lighting, instrumentation, control panels, and light industrial equipment.

But once your system exceeds around 15–20 kVA, inefficiencies multiply:

Voltage drops increase.

Line losses grow due to higher current per conductor.

Heat dissipation becomes harder to manage.

By contrast, three-phase systems distribute the total load evenly across three windings, each carrying one-third of the total current. This lowers I²R losses and keeps the transformer cooler, allowing for smaller conductors and longer cable runs without significant voltage drop.

Practical Applications

|

Application Type |

Recommended Transformer |

Typical Rating Range |

Notes |

|---|---|---|---|

|

Domestic & small commercial |

Single-phase |

0.5–10 kVA |

Suitable for standard AC supplies, lighting, and office equipment |

|

Workshops / garages |

Either, depending on load |

5–20 kVA |

If running small motors or welders, three-phase improves efficiency |

|

Three-phase |

10–500 kVA+ |

Reduces motor vibration and current imbalance | |

|

Data centres / continuous operations |

Three-phase |

50–1000 kVA |

Balanced load improves power quality and uptime |

|

Marine / transport systems |

Three-phase |

Custom |

Ideal where weight and efficiency are critical |

Magnetic Core Design Differences

Both transformer types share similar construction, laminated steel cores and copper (or aluminium) windings, but the core configuration changes:

Single-phase transformers use one magnetic core limb carrying both primary and secondary windings.

Three-phase transformers can be built as a single three-limb core (shared magnetic path) or as three individual single-phase units connected in a bank.

A shared three-limb design is lighter and more compact, but using separate single-phase units allows modular servicing and redundancy, a very important consideration for continuous-operation facilities.

Voltage Stability and Harmonics

Three-phase transformers provide better voltage regulation underload, because power transfer is continuous across phases.

This means:

Less flicker and voltage sag under high demand.

Lower total harmonic distortion (THD).

Reduced neutral current when loads are balanced.

Single-phase systems, by comparison, are more sensitive to transient spikes and harmonic distortion, especially when running non-linear loads (like variable frequency drives, LED lighting, or computers).

If you’re designing for precision equipment or data reliability, go three-phase every single time.

Cost vs Lifetime Value

Upfront, a single-phase transformer is cheaper to buy and install, but over time, the three-phase option usually wins out due to:

- Lower energy losses (5–10% efficiency gain in most real-world setups)

- Smaller conductor size requirements

- Less maintenance (because of lower heat cycling and winding stress)

Over a 10-year operating window, that difference can translate into thousands in energy savings, particularly for industrial and 24/7 systems.

When to Use Each Transformer Type = The Quick Guide

Use single-phase when:

- Your total load is modest (<10 kVA)

- The system feeds lighting, control panels, or single-phase equipment

- Simplicity and cost are priorities

Use three-phase when:

- You’re driving motors, compressors, HVAC, or high-demand systems

- Power efficiency and load balance matter

- You want flexibility to scale your system later

Custom Transformer Design with Majestic

Every site has different power conditions, load profiles, inrush currents, harmonics, and ambient temperatures all play a part. That’s why Majestic Transformer Co manufactures both standard and bespoke single- and three-phase transformers built to BS EN 61558, BS EN 60076 standards and all with an ISO 9001:2015 quality system meaning that you will get a well-built unit capable of running for many years.

We can design, prototype, and deliver:

- Isolation and auto-wound types

- Step-up or step-down configurations

- Air-cooled designs

- Custom enclosure and mounting options

Whether you’re modernising an old installation or specifying a new system, we’ll help you get the efficiency, safety, and performance balance right.

Request a Quote or speak with our design team to specify your ideal transformer